ISSS MEMS Community chip

Introduction:

The ISSS MEMS Community chip activity was started in the year 2011- 2012 under the NPMASS programme by the Govt of India and under the supervision of professors from the Indian Institute of Science and Dr.V K Aatre. The initiative was taken to help career-oriented engineering educational institutions to fabricate microelectromechanical systems (MEMS) devices and get enable them to undertake full-fledged research activities.

What is a “Community Chip”?

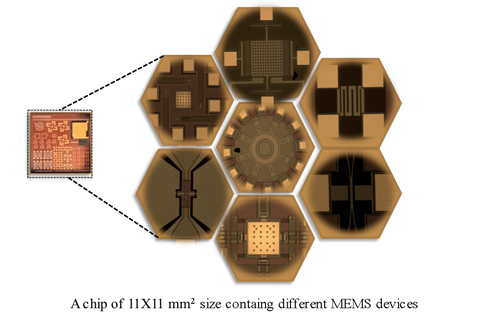

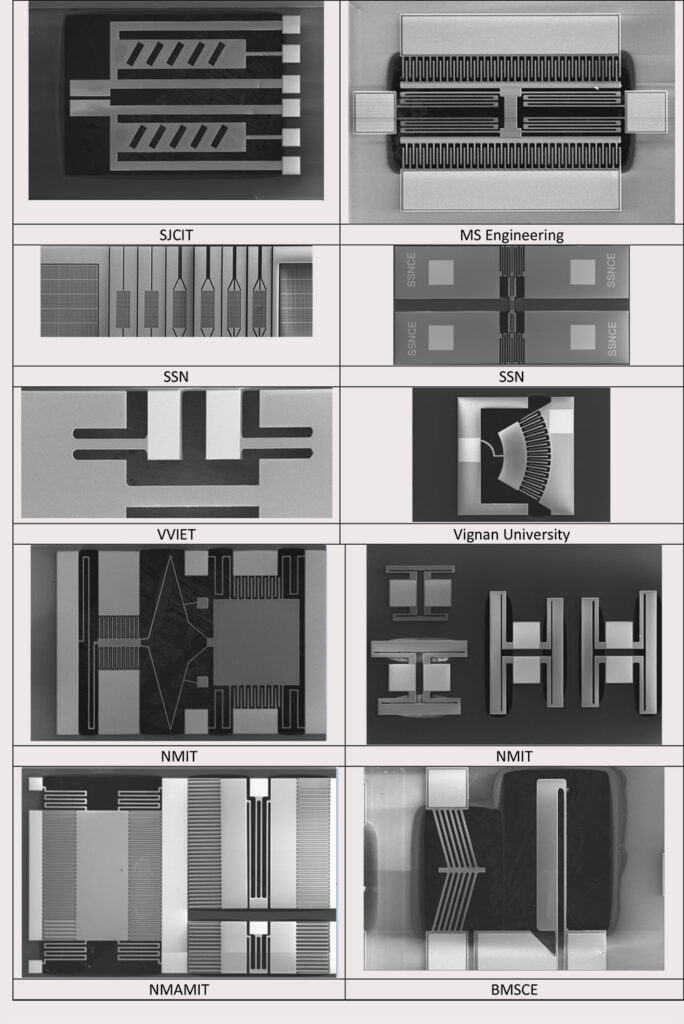

A chip where MEMS device designs from multiple users from different institutions are put together on a single-chip (chip area = 11 mm ×11 mm;see the image below). These MEMS devices are fabricated using standard Multi-User MEMS Processes (MUMPs) such as SOIMUMPs; PolyMUMPs; PiezoMUMPs; & MetalMUMPs at MEMSCAP, by MEMSCAP, a US-based MEMS manufacturing service (http://www.memscap.com/).

Community Chip Activities in India

Participating Institutes

- Anna University, Chennai

- Bengal Engineering and Science University, Shibpur

- Kurukshetra University, Kurukshetra

- Nitte Meenakshi Institute of Technology, Bengaluru

- Rajalakshmi Engineering College, Chennai

- SGS Institute of Technology and Science, Indore

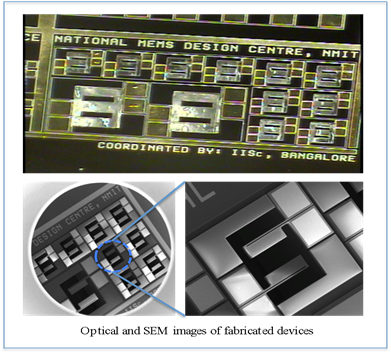

Process: SOIMUMPs

- Number of Institutions participated: 8

- All MEMS devices were thermal actuator

This run was coordinated by Prof. K. J. Vinoy, Prof. G. K. Ananthasuresh, Dr. Samdudha Khan, Dr. Sudhanshu Shekhar from IISc and was sponsored by NPMASS.

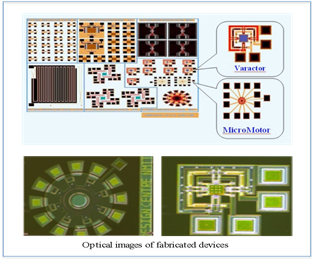

Participating Institutes

- Varactor & Micromotor – NMIT

- Micromirror – Institute of Radiophysics and Electronics, University of Kolkata

- Gyroscope & Microheater – Rajalakshmi Engineering College

- Microgripper – Anna University

- Optical Coherence Waveguide – SGSITS

- Shunt-capacitance RF MEMS switch – BESU

Process: PolyMUMPs

- Number of Institutions participated: 6

This activity was coordinated by professors and research scholars from IISc (Prof. K J Vinoy, Prof. G. K. Ananthasuresh, Dr. Samdudha Khan, Dr. Sudhanshu Shekhar) along with professors from NMIT (Prof. S. L. Pinjare and Prof. Veda S. N.) and sponsored by NPMASS.

Participating Institutes

- Energy Harvester – Anna University, Chennai

- Microheater – Bengal Engineering and Science University, Shibpur

- Microphone – Nitte Meenakshi Institute of Technology, Bengaluru

- Accelerometer – Rajalakshmi Engineering College, Chennai

- RF Switch – SSN, Chennai

- Bidirectional Actuator – Kurukshetra University, Kurukshetra

- Resonator – NIT, Trichy

- Thermal Actuator – Basaveshwara Engineering College, Bagalkot

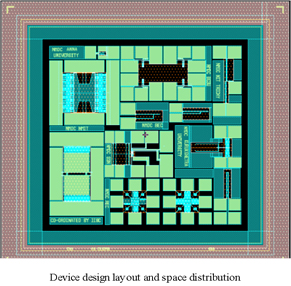

Process: SOIMUMPs

- Number of Institutions participated: 8

This activity was coordinated by professors and research scholars from IISc (Prof. K J Vinoy, Prof. G. K. Ananthasuresh, Dr. Samdudha Khan, Dr. Sudhanshu Shekhar) along with professors from NMIT (Prof. S. L. Pinjare and Prof. Veda S. N.) and sponsored by NPMASS.

Participating Institutes

- Accelerometer and Thermal actuator – Nitte Meenakshi Institute of Technology

- Heatuator – BMS College of Engineering

- Microgripper – SJC Institute of Technology

- Inertial sensor – Vignan University

- Accelerometer – NMAM Institute of Technology

- Electrostatic Actuator – MS College of Engineering

- Microfluidic channels – SSN College of Engineering

- Directional Microphone – Vidya Vikas Institute of Engineering and Technology

Process: SOIMUMPs

- Number of Institutions participated: 8

Prof. G. K. Ananthasuresh and Dr. Sudhanshu Shekhar along with Prof. Veda S. N. coordinated the whole activity under the umbrella of the Institute of Smart Structures and System (ISSS). Participating institutes financed the fabrication cost of this run.

ISSS’s Role in community chip

ISSS is able reach out to various institutions across the country. Through foundation courses being conducted online, students as well as faculty across the country are trained on MEMS design and other aspects of fabrication. Also, ISSS provides support to design at various stages and finally the corrected designs are collated and sent for fabrication. ISSS also facilitates the participants in testing and characterizing the fabricated devices.

Future activities

So far, for every run of the community chip, we have depended on MEMSCAP. Dependancy on a foreign foundry leads to high fabrication cost and longer turn-around time. Now, we would like to fabricate the upcoming community chip at CeNSE-IISc. This will be done is phased manner in the upcoming days with workshops, training programmes and fabrication at affordable prices. We would also be looking at giving discounts to ISSS members / corporate members. For more details one could contact ISSS at admin@isssonline.in.